Leaks are more than a nuisance. Damage caused by water intrusion is the single most costly driver of construction defect litigation, totaling billions of dollars over the last 20 years. That’s why it’s critical to ensure that a property’s building envelope systems are not only designed to withstand the elements but are also installed for optimal long-term performance and leak prevention.

VERTEX’s Building Envelope Services includes field performance testing, which does just that. The field testing gives the owner the assurance that the installed windows, doors, and other building envelope components have been built per the contract documents and will perform to meet the industry-standard guidelines set forth by the design professional.

One set of tests we often perform for our builder clients is field testing for air and water infiltration of newly installed window assemblies. One of the specifications we follow is AAMA 502.

How Field Performance Testing Works

Unlike laboratory testing, field inspectors visit the construction job site where the final assemblies are installed on the building. Like building scientists, the inspectors follow a set of specific procedures established by industry standards and record the results.

In the case of window field performance testing, after arriving on the project the inspectors record the location and condition of the window, documenting all observations, and test the window’s basic functionality by opening and closing it five times. Then our team tests the assembly to verify two performance ratings: air infiltration and water penetration.

Air Infiltration Test – ASTM E783

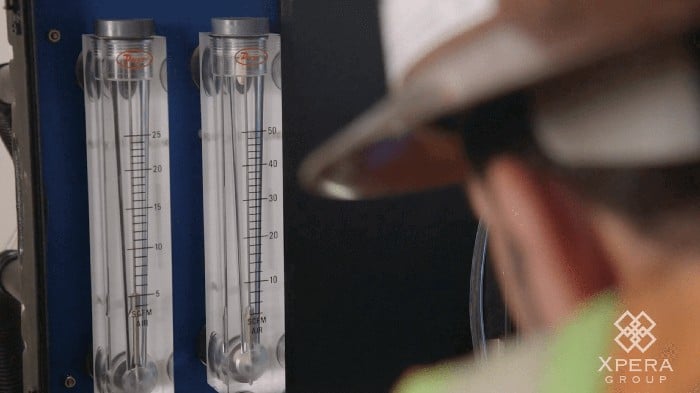

Starting with air infiltration, our inspectors follow the instructions of ASTM E783, the standard test method for air leakage through installed windows and doors. The team mounts an assembled chamber that is used to create the difference in air pressure in the test. The chamber is sealed against the wall around the assembly. Depending on conditions, the chamber may be mounted on the inside or on the exterior wall. With the chamber in place, a calibrated air supply or extraction machine and pressure measuring device is connected to the chamber to record and monitor the pressure differential.

We then turn on the supply air system to create the specified difference of pressure for two instances: one with the window sealed and the second with the seal off to gauge the air leakage. The calculations made will verify if the window passes the air infiltration performance test.

Water Penetration Test – ASTM E1105

For the water penetration test, we follow the procedures detailed in ASTM E1105 — Standard Test Method for Field Determination of Water Penetration of Newly Installed Windows, Doors, and Curtain Walls. Using the same chamber and supply air system from the previous test, we now involve a laboratory-calibrated spray rack.

The spray rack is placed outside the assembly at a calibrated nominal distance. We then use the supply air system to create a uniform or cyclic static air pressure differential and spray water against the window with the rack at the specified standard rate of 5 gallons per square foot per hour. With the combined equipment running to simulate a major rainstorm, the test is performed, with our inspector(s) carefully observing and documenting any water intrusion that might occur.

If no water leakage is observed, the window passes the water performance test. But, if water is observed, our field specialist documents where it is coming from in order to diagnose the problem areas.

During the field testing, the specimen performance and test procedures are photographed, field notes and drawings and prepared, and a formal report is provided to the client.

How Can VERTEX Help?

VERTEX is pleased to be able to offer this specialized service to our builder clients, providing the peace of mind that comes from knowing that their critical building envelope systems will stand the test of time—and the elements.

To learn more about VERTEX’s Quality Assurance Services or to speak with a Construction Expert, call 888.298.5162 or submit an inquiry.

Author

Bill Kopperud

Building Envelope Consultant/Inspector, Xpera Group

This article was originally published by Xpera Group which is now part of The Vertex Companies, LLC.